Description

Product Details Introduction

Main technical parameters

|

Main technical parameters of aerial work vehicle |

||||

|

class |

project |

unit |

data |

|

|

Size parameters |

cabinet minister |

mm |

5995 |

|

|

total width |

mm |

2090 |

||

|

overall height |

mm |

3160 |

||

|

mass parameter |

Number of passengers (including driver) |

human being |

2/3 |

|

|

gross mass |

kg |

4495 |

||

|

Main performance parameters |

Rated load of the work platform |

kg |

200 |

|

|

Maximum operating altitude |

m |

30 |

||

|

Maximum working height is the working amplitude |

m |

4 |

||

|

Maximum operating range |

m |

23 |

||

|

Maximum operating height at maximum operating amplitude |

m |

19 |

||

|

Leg span |

broadwise |

mm |

5400 |

|

|

direction |

mm |

5100 |

||

|

The work platform rotates |

o |

360 |

||

|

Boom swing time |

s |

60≤t≤80 |

||

|

Climbing arm extension time |

s |

70≤t≤90 |

||

|

Lift arm rotation speed |

s/r |

120≤t≤160 |

||

|

Time to retract and extend legs |

s |

50≤t≤60 |

||

|

Driving parameters |

front overhang |

mm |

1130 |

|

|

rear overhang |

mm |

1565 |

||

|

protract |

mm |

/ |

||

|

Stretch back |

mm |

/ |

||

|

wheel base |

mm |

3300 |

||

|

Maximum speed |

km/h |

90 |

||

|

Minimum ground clearance |

mm |

220 |

||

|

approach angle |

o |

18 |

||

|

departure angle |

o |

14 |

||

Configuration description

Main configuration components

|

RRR5040JGKG Main configuration of high-altitude work vehicle |

|

|

Component name |

Brief description |

|

batholith |

The Dalian CGC1041HDD33F is a second-class chassis |

|

engine |

Q23-132E60 full diesel 132hp engine, National VI emission standard |

|

Cabin configuration |

Single row seat, the number of passengers is 2-3, and the cab is equipped with air conditioning |

|

Fencing and walkway |

Stainless steel fence, aluminum alloy anti-slip walkway |

|

Power take-off system |

Pneumatic power take-off |

|

foot platform |

1600x700x1000mm (the size of the basket can be customized according to customer requirements) |

|

Arm type |

Six sections of 14-sided synchronous telescopic arms |

|

rotator |

360. Continuous rotation |

|

landing leg |

The front V and rear V types can be adjusted separately and can be extended synchronously |

|

operate |

The rotary platform is fixed for operation, the wireless remote control box is operated, and the hydraulic handle of the vehicle is operated. An electric emergency pump is provided, and the whole vehicle can realize full hydraulic and electric emergency operation. |

|

navar |

The high altitude vehicle control system developed by Ryaet is highly stable |

|

Leveling system |

Automatic hydraulic leveling |

|

Tension chain force balance |

The rope is stretched to set the balance mechanism to ensure that the force on the left and right steel cables is balanced |

Basic functions and safety configuration

|

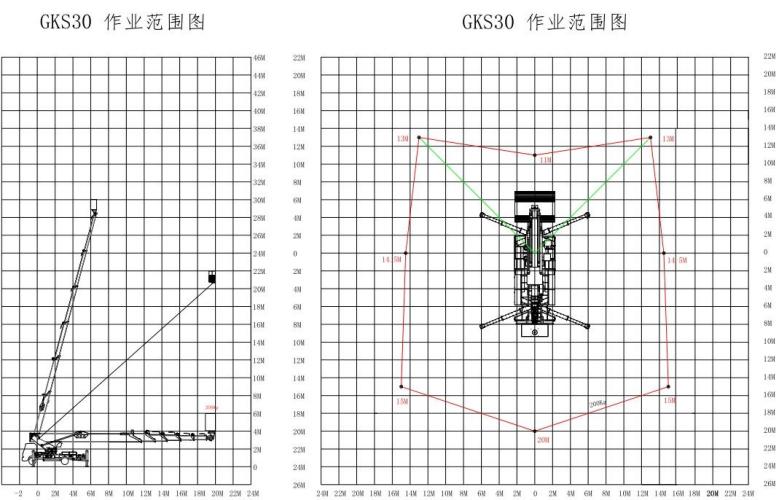

Safety configuration of the basic functions of RRR5040JGKG type aerial work vehicle: The platform load of the aerial work vehicle can be 200kg, the maximum working height is 30m, the maximum working amplitude is 23m, and the boom amplitude Angle range is-18 ~ 80. The working platform hydraulic leveling is automatic. |

|

|

name |

Brief description |

|

Leg support and leg weakness test |

The force state of the support leg is detected in real time. Once the alarm limit is detected, the support leg is moved |

|

Automatic interlock device for getting on and off the vehicle |

Automatic lock-in and lock-out of boarding and alighting to prevent simultaneous operation of boarding and alighting and realize safety protection |

|

Emergency electric hydraulic pump |

When the chassis engine or hydraulic master pump fails, the crew is sent back to the ground |

|

Emergency stop device |

Three emergency stop devices to ensure that all operations are stopped in case of emergency |

|

Automatic limiting |

Ensure that the vehicle operates within a safe operating range |

|

Vehicle level status tester |

It can detect the lateral and longitudinal inclination state of the vehicle |

|

Engine ignites and shuts down |

The turntable and remote control box can be used to start and stop the engine |

|

composite move |

Combined movements such as platform rotation, turntable rotation, boom amplitude and extension can be performed simultaneously |

|

Break chain protection device |

The tension rope is set to balance the force on the left and right steel wire ropes |

|

Electrical emergency operation function |

In case of emergency, the vehicle action is restored to ensure that personnel can be safely sent back to the ground in dangerous working conditions |

Introduction of main features

Type RRR5040JGKG aerial work vehicle is the latest product of Hubei Ruiyate Automobile Co., LTD., which integrates a variety of functions and leads domestic products of the same level in parameters and performance. Its main features are:

1. The classic continuation of blue plate cars

The RRR5040JGKG type aerial work vehicle is a blue plate 30 meters, which continues the classic of Riet Blue Plate 23 meters, 25 meters and 27 meters, and is another classic blue plate product built on this basis.

The vehicle has good driving performance and a length of less than 6 meters. It can be equipped with chassis such as Dayun and Jiangling, providing customers with a variety of choices and meeting the needs of a light type telescopic arm product with blue plate.

The car is equipped with a 1.6 meter stainless steel working platform (2 meters folding working basket can be selected according to customer requirements), large space and good corrosion resistance, convenient for customers to use.

The maximum working height of the vehicle can reach 30 meters, and the maximum working amplitude can reach 23 meters. The vehicle adopts the partition working type to meet the different working needs of customers and ensure the safety of customers.

2. Simple and fashionable appearance, high-end and grand

The product design is mainly guided by lightness and speed. The new boom style adopts the most advanced design concept and manufacturing process in Europe for the arm section. The boom and turntable adopt the external folding polygonal structure, the boom adopts high strength steel, with high safety coefficient. It has good stiffness and strong stability.

The open design of the car allows for easy maintenance of the chassis. The on-board telescopic system (wire rope system) and special pipeline conveying system are all built-in, which not only makes the appearance of the vehicle neat and beautiful, but also effectively reduces the long-term exposure to sun and rain for the above-mentioned mechanisms, reduces accidental scratches during work, and extends the service life of the vehicle.

The upper and lower structure of the vehicle is full in shape, with a harmonious proportion. The color is mainly gray and yellow, clean and generous. The small stainless steel fence and side protection are used to get off the vehicle, combined with aluminum alloy platform, making the whole vehicle more high-end, fashionable and atmospheric.

3. Good working performance and large operating area

The maximum working height of RRR5040JGKG type aerial work platform is 30 meters, and the maximum working amplitude is 23 meters. This vehicle adopts six sections of fourteen-sided telescopic arms for synchronous extension and contraction, which is simple in action, easy to operate, quick in action, and has a large working range; the working platform is placed at the rear, making it convenient for personnel to get on and off.

4. Unique and novel boom structure

Compared with other domestic manufacturers of the same class blue plate, we have the following unique features:

(1) The arm frame adopts the original 14-sided bending design and processing technology, especially the bending of the lower channel steel of each section of the arm. After sufficient theoretical analysis and 100,000 fatigue tests, different arms have different bending numbers to ensure less deformation, high strength, good motion stability and high safety.

(2) The arm frame is made of high strength steel plate to effectively ensure the safety of operation.

5. Reliability and security

(1) The drag chain used in the whole vehicle dedicated pipeline conveying system is imported brand, with high reliability.

(2) During the product development process, methods such as structural safety verification, stability analysis, and reliability testing are employed to ensure that the product\’s stability and performance are reliable within the operational range. Before leaving the factory, in addition to overload testing, dynamic loads at 1.25 times the rated load and static loads at 1.5 times the rated load are also conducted. All critical structural components undergo tens of thousands of fatigue cycles and destructive tests to ensure the safety and reliability of the equipment.

(3) The safety device is complete, including the hydraulic cylinder stopback device, leg stopback device, upper and lower vehicle interlock device, emergency stop device, soft leg protection device, extreme deceleration, emergency manual operation and other safety protection system to ensure the safety of high-altitude work.

(4) The car is fully equipped, including high-grade mudguard, off-car operation box, etc.

(5) All key structural parts are made of low alloy high strength steel welding, with high strength and light weight. After a variety of tests, it has been fully verified to ensure accurate matching of structure, electrical and hydraulic components. All main control components and key transmission parts are made of internationally renowned brands, with stable quality and high reliability.

6. Wireless remote control, comfortable and convenient for one-handed operation

Wireless remote control technology ensures that the operator can operate flexibly and conveniently in a narrow working environment, eliminate blind spots, better working vision, and avoid the operator to endure cold and hot weather, can be selected in a suitable place to complete the operation; one hand can complete

Complete the active operation.

7. Fast action and can achieve compound action

There are two options for the speed of leg retraction and extension. When the speed is high, the total time of retraction and extension is less than 75 seconds. The boom can be extended and reduced quickly, and the rotary table rotation, boom extension, boom extension and platform rotation can be realized synchronously, which improves the operation efficiency.

8. Smooth work

(1) Start stop with buffer control to reduce the impact of action;

(2) The leg is controlled by a proportional directional valve to control the flow rate;

(3) The balance valve is used to control the start and stop of each action of the arm frame to ensure the stability of the start and stop action;

(4) Load sensitive proportional valve is adopted to match the flow rate and speed reasonably;

(5) The hinge point is arranged reasonably, the boom amplitude has no sudden pressure change, the pressure changes uniformly, and the action is stable.

9. Good ergonomics to improve safety and comfort

(1) Seats and foot pedals are set up at the rotary table operation place to rotate with the rotary table, so that the staff can operate more comfortably and reduce the fatigue degree of the staff working for a long time.

(2) The color matching of the control box interface of the turntable is in line with human visual sense, which reduces visual fatigue and improves safety and comfort. The operation interface combines graphics and text, which is simple and easy to understand, reduces misoperation, and improves safety and comfort.

(3) The height of the car operation box is in line with the operator\’s operating height habit. The operation box is equipped with a level, and the operation mark is simple and clear.

(4) A large toolbox is equipped on the right side of the car body to facilitate customers to store tools with the car.

Scope of work map

Rated load 200kg

Product Details Display

Reviews

There are no reviews yet.