Description

Product Details Introduction

Introduction of compressed garbage semi-trailer pr- oducts

1. Product overview

The newly developed rear-mounted compressed waste semi-trailer is used in conjunction with the corresponding tractor. The vehicle is connected to the tractor via a drawbar, and also needs to be connected to air hose fittings, ABS fittings, electronic control fittings, hydraulic oil pipe fittings, etc. The vehicle is equipped with two power systems: one uses an external 380V power source, driven by an electric motor to operate the hydraulic system; the other draws power from the tractor\’s chassis transmission to drive the hydraulic system, completing the work cycle。

2. Functional Overview

It has many functions such as garbage collection, automatic loading and compaction of garbage, garbage transfer and dumping.

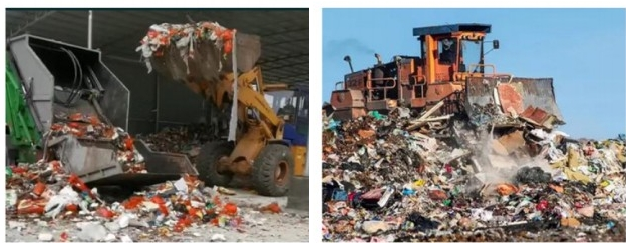

Scope of application

Using a loader or rear-mounted ZZZ for loading can replace a transfer station, serving both as a transfer station and a station, suitable for long-distance collection and transportation of large volumes of waste. It is not suitable for the transfer operations of construct- ion waste, industrial waste, food waste, and hazardous waste speci- fied by the state. Environmental temperature requirements: it is recommended to operate in an environment with temperatures ranging from 0 to 40 . When the ambient temperature falls below 0 , there is a risk of freezing inside the container, which could damage the hydraulic cylinders or make unloading difficult.

Iv. Main structure and performance characteristics

The compression garbage semi-trailer is mainly composed of semi- trailer frame, garbage box, filler, shovel, hydraulic cylinder bracket, hydraulic system and electrical system, etc. The specific introduction is as follows

1 、 Half trailer frame (lower frame part)

The semi-trailer chassis is the critical component for the load- bearing and transportation of compressed waste semi-trailers, playing a vital role in transport safety and reliability. Its structure mainly includes the frame, axle, tires, suspension, drawbar, outrig- gers, braking system, guardrails, sewage collection tank, and signa- ling devices.

The bottom frame of the semi-trailer is specially designed according to the requirements of the whole vehicle and the assembly characteristics of the garbage box, that is, it meets the design specifications of the semi-trailer and meets the requirements of the use of the compressed garbage semi-trailer.

The semi-trailer chassis is bolted to the garbage bin for easy assembly and disassembly; the semi-trailer chassis is connected to the tractor with standard drawbar pins to achieve towing functional- ity. Additionally, it uses pneumatic connectors, ABS connectors, electronic control connectors, and hydraulic pipe connectors to control electrical, pneumatic, hydraulic, and braking systems. A support device is installed at the front of the semi-trailer chassis to support the trailer when it detaches from the tractor.

2 、 Upper garment structure push shovel

The shovel is made of high-quality profile and weather-resistant steel panel welded together. It is the part that performs the unloading operation of the product. The shovel is arranged inside the garbage box and slides along the track of the garbage box under the drive of the hydraulic cylinder to complete the unloading operation.

dustbin

The trash bin is the component for collecting and storing household waste, serving as the connection base for important parts such as fillers. Its rational structural design and material select- ion ensure optimal product performance; the inner cavity uses high- quality corrosion-resistant weathering steel, which has high streng- th, strong corrosion resistance, and a long service life. The side panels are made using whole plate forming technology and an integra- ted frame design, ensuring manufacturability while enhancing aesthe- tics; the bottom of the trash bin is equipped with an independent filler locking mechanism.

precompressor

The filler is the component of this product that compresses and reduces the volume of household waste. The compression mechanism on the filler completes the compression and loading of waste into the bin through the sliding movement of a slide plate and the rotation of a scraper. A sewage tank is designed at the bottom of the filler to enhance the product\’s wastewater storage capacity; the filler hopper section uses high-hardness wear-resistant steel, which increases the durability of the product.

Cylinder bracket

The middle part of the cylinder bracket is fixed to the middle part of the multi-stage cylinder, following the movement of the middle part of the cylinder and supporting the downward force caused by the weight of the cylinder, thereby improving the force distribu- tion during the operation of the cylinder; nylon sliders are instal- led on both sides of the cylinder bracket, which work in conjunction with the guide rails on bot

|

Projec t |

U n i t |

Parameter |

||

|

Vehicle parameters |

Curb weight |

K

G |

15800,15200,14500 |

|

|

Gross mass |

K

G |

40000 |

||

|

Rated load mass |

K

G |

24200,24800,25500 |

||

|

Size (excluding towing vehicle) |

m

m |

12365*2550*3850 |

||

|

Operational performance |

Reduce cycle time |

S |

23 |

|

|

Unloading cy- cle time |

S |

200 |

||

|

Effective vol- ume of garbage can |

m

3 |

42 |

||

|

System press- ure |

M P a |

22 (large pump), 22 (small pump) |

||

|

Fill the width of the feed opening |

m

m |

2070 |

||

|

External power supply pressure |

V |

380 |

||

|

Lift height at unloading |

m

m |

6400 |

||

|

Load the vehi- cle length |

m

m |

14750 |

||

|

|

Go |

Maximum design speed |

k m / h |

89 (with tractor) |

|

|

Minimum turning radius |

m |

10 |

★ Basic configuration of products

|

Order |

Configure the |

Configuration de- |

|

number |

name |

scription |

|

1 |

Box |

The standard side plate of the box is 4MM T700 high strength plate, and the thick- ness of the hopper is 5MM T700 High strength plate |

|

2 |

Axle |

The standard configuration is Zhongxing 13 ton axle with 3 drum brakes * |

|

3 |

Laminated sp- ring |

The standard size is 16MM*8 pieces |

|

4 |

Suspension |

The standard is 180 mechanical suspens- ion |

|

5 |

Landing leg |

The standard is a domestic 28-ton single- action leg |

|

6 |

Pulling line |

The standard is domestic 50# or 90# tra- ction pin |

|

7 |

Tyre |

The standard is 425/65R22.5 20PR*6 |

|

8 |

Steel ring |

The standard is 9.0-22.5 steel rim (14MM thick) *12 |

|

9 |

Turning radius |

8.00 MIL-10.00 meters (for reference only) |

|

10 |

Cabin dimens- ions |

11000*2300*2100mm |

|

11 |

Working size |

Loading work size: 14750**2550*3850 (rear large bucket down) Unloading working size: 12365*2550*6400 (filler lifting) |

|

The other standard configuration is: manual + remote control operation; with ABS; the appearance of the vehicle includes edge lights, wheelbase, wheelbase, box and trailer size are all made in strict accordance with the announcement requirements. |

||

VI. Main advantages of the product 1 、 Superior performance

High load capacity

The effective volume of the garbage bin reaches 42m3; the vehicle size is short, the self-weight is light, the compression force is large, and the loading capacity is strong. It is more suitable for old incineration power plants and small and medium-sized waste transfer stations with limited sites, long-distance transportation, and can bring greater economic benefits to customers under standard load.

Economical

A traction car can be equipped with multiple compressed garbage semi-trailers, which can be used for more than one purpose. The compression cycle is driven by an external power supply of 380V. The traction car is only responsible for unloading operations, and the energy consumption of the whole vehicle is lower.

Good connectivity (1) Unique filler, the left and right side panels are raised to avoid garbage falling from both sides; (2) fully sealed

The sealed back flip mode ensures that the seal does not leak material;

high efficiency

After the use of post-ZZZ or loader feeding, the amount of garbage pressed into a single time is large, and the filling operation cycle time is less than 23s. The whole garbage collection and transporta- tion process is efficient and fast.

High intelligence

The tail control box is designed with multi-function integration, the rear flip device is fully sealed and large bucket type, and the one-button automatic opening and closing function is provided for more intelligent and convenient operation.

The new shape of the box adopts the leading integral frame struct- ure design, with large overall rigidity, high strength and good processability; the filler adopts the wrapping shape design, with overall grandeur, simplicity and beauty.

low noise

Equipped with high quality low noise multi-way valve, effectively eliminate the fluid impact noise in the hydraulic shifting moment; at the same time, through the matching optimization of the hydraulic system, reasonable selection of motor working speed, the vehicle noise is low, to avoid the problem of operation noise disturbing the people.

High Environmental Protection (1) Independent locking mechanism and excellent sealing technology. To ensure the seal of the rear face of the garbage bin and prevent sewage from leaking out, an innovative independent locking technology has been designed to secure the filler. The sealing strip at the interface between the rear face of the garbage bin and the filler remains in a compressed state, ensuring good sealing performance between the filler and the garbage bin. Additionally, the sealing strip is made of special rubber material, providing excellent sealing performance and effectively preventing secondary pollution. (2) The rear flip completely covers the filler\’s feeding port, eliminating dust and debris caused by exhaust gas turbulence during transportation, while also reducing odor pollution. (3) The entire vehicle makes full use of the space, with oversized sewage tanks designed under both the garbage bin and the filler, ensuring strong sewage capacity. (4) The entire vehicle uses electric motors to drive the hydraulic system, reducing enviro- nmental pollution.

2. Good quality

Unique filler track design

The filling plate track is designed with special profile and integ- ral molding, which has high strength, good bearing capacity and long service life. It has strong corrosion resistance and wear resistance The steel plates that come into direct contact with garbage, such as dustbins and shovels, are made of high-quality weathering steel with strong corrosion resistance, high ultimate strength and excellent corrosion resistance, which ensures a long service life. They are especially suitable for corrosive working environments. The filling bin positions are made of high-hardness wear-resistant steel, which improves the durability of the product.

High quality key components

The key components such as electrical system and hydraulic system are made of high quality domestic and foreign famous brands, which ensures the reliability of use.

High quality multi-way valve

The product is equipped with high quality low noise multi-way valve, which can effectively eliminate the fluid impact noise in the instant of hydraulic shifting, and improve the disturbance problem of current garbage truck products.

Advanced control technology

Distinguished from the traditional PLC control mode commonly adopted in the industry, this product draws on advanced and mature foreign technologies, adopting the current \”CAN bus + dedicated controller mode.\” It boasts high automation, excellent reliability, low failure rates, and a long service life. The power output control of the generator (or motor) is achieved through an electrical system for fully automatic control, ensuring that the generator (or motor) can automatically select between acceleration and idle states during various operational co

Product Details Display

Reviews

There are no reviews yet.