Description

Product Details Introduction

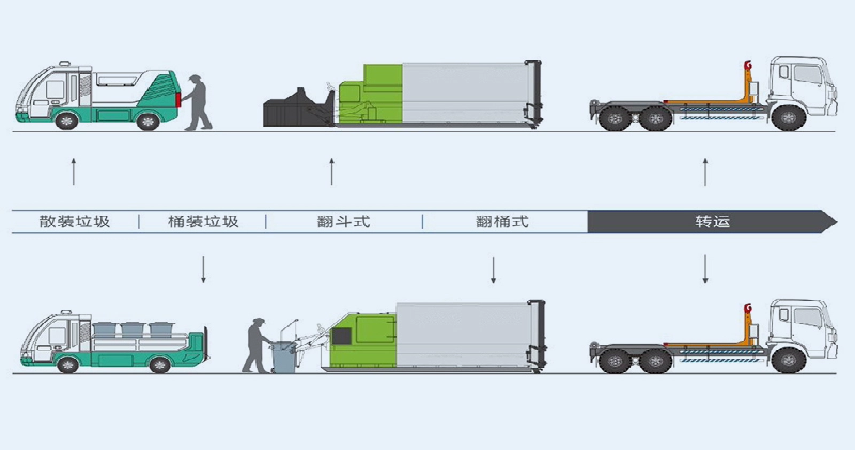

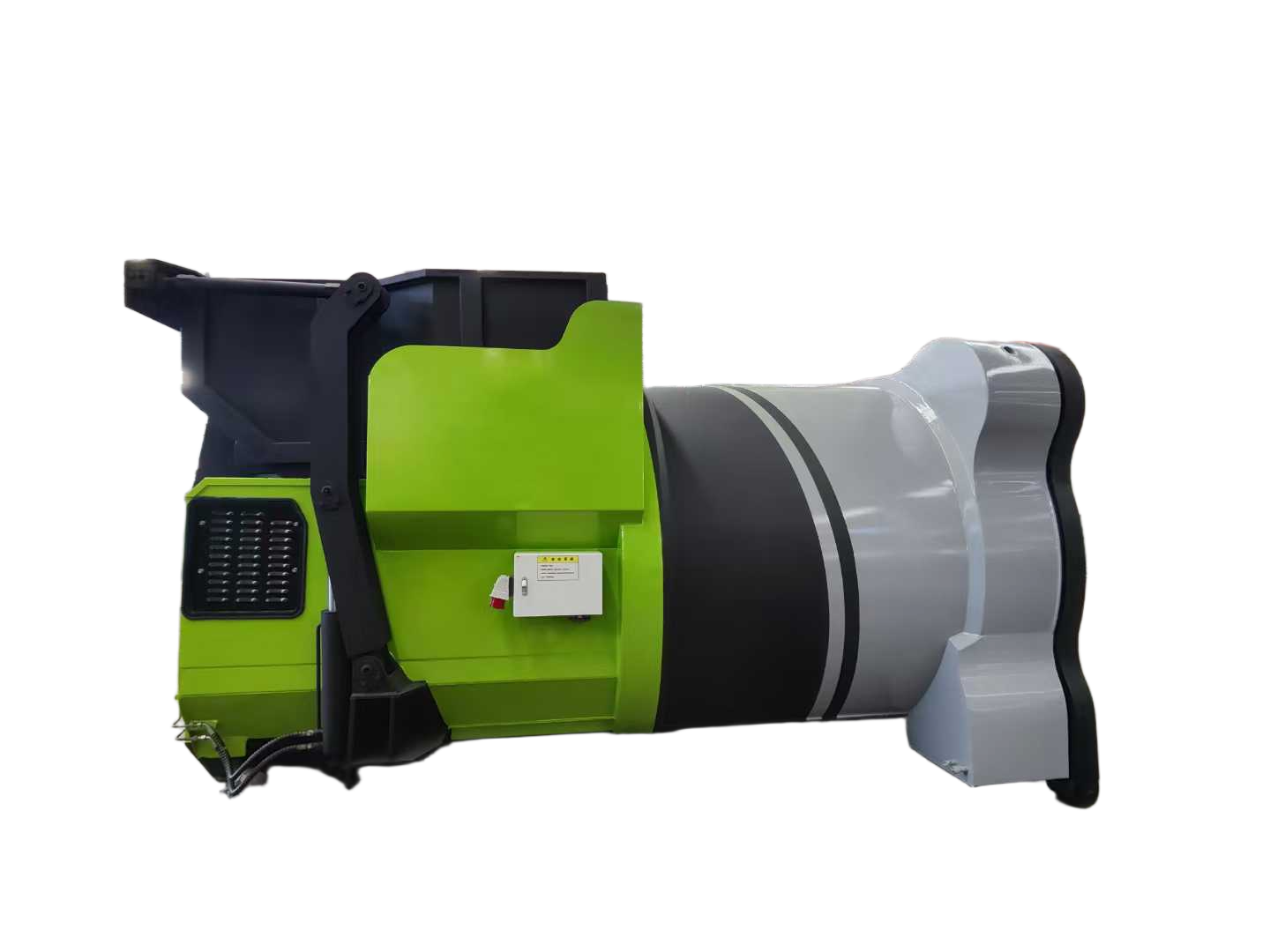

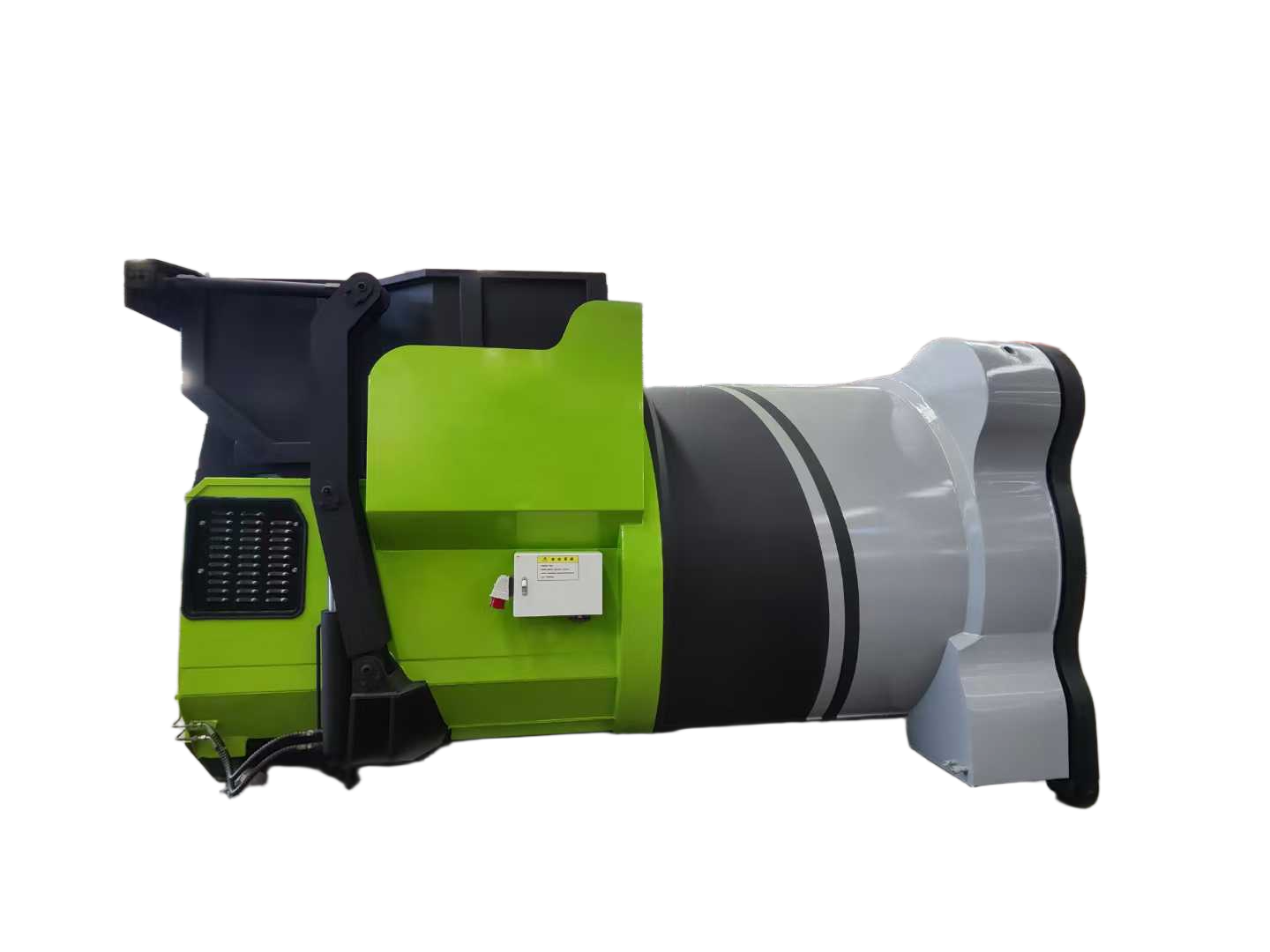

The mobile compression station is an advanced technology developed by our factory, designed to be used in conjunction with detachable garbage trucks. The product features an attractive appearance, rational structure, easy operation, high efficiency, and high reliability, with a wide range of applications. It has won the favor of sanitation departments and a broad user base. The product effectively addresses issues related to the collection, compression, and transportation of urban and rural waste, making it highly valuable for use and promotion.

Good versatility: the equipment has good general matching, which can be matched with hydraulic pull arm hooks produced by many manufacturers in China that meet the requirements of bidding documents and have hook center height of 1570mm.

High applicability: the equipment covers a small area, only needs to lay simple ground steel plate rail, no need for embedded parts, can be quickly installed and used; suitable for garbage cans, hand carts, mini collection vehicles feed, compaction density 0.65-0.85t/m3.

High Flexibility: The equipment can be moved to different locations as needed, making it suitable for temporary large gatherings such as flower markets and exhibitions. It can handle various types of waste disposal, including small carts, board carts, four-wheeled mini garbage trucks, and four-wheeled agricultural garbage trucks, with the capability to crush bulky waste. This device is primarily designed for solid waste collection and transportation at urban sanitation stations, residential areas, communities, hospitals, schools, and large venues. It is especially suitable for frequent waste disposal in small quantities (around 2 cubic meters) in city districts.

Equipment composition: The mobile garbage compression equipment is composed of a flipping mechanism, a compressor head, a container and a rear door (unloading door) and is integrated into one. It is controlled by PLC, and the motor, oil pump and valve are imported famous brand products.

List of power units

|

order number |

name |

Specifications/model |

quantity |

supplier |

|

1 |

gear pump |

PLP20.14 |

1 |

casappa |

|

2 |

any power-generating or power-driven machine |

1TL0001-1CB23-3FA4-Z |

1 |

siemens |

|

3 |

Oil filter |

HHX-160×180-J |

1 |

auroral |

|

4 |

content gage |

YWZ-80T |

1 |

auroral |

|

5 |

air cleaner |

PAF1-0.02-0.55-40L |

1 |

auroral |

|

6 |

Return oil filter |

HH-100×10 |

1 |

Hydfly |

|

7 |

overflow valve |

RVCO.M22.OG.000 |

2 |

VIS |

|

8 |

pressure pickup |

550.954S03S421 |

1 |

HUBA |

|

9 |

electromagnetic directional valve |

HH021001 |

1 |

ATOS |

|

10 |

electromagnetic directional valve |

HH621060 |

1 |

ATOS |

|

11 |

electromagnetic directional valve |

HH131060/1 |

1 |

ATOS |

|

12 |

electromagnetic directional valve |

HH021060/1 |

1 |

ATOS |

|

13 |

check valve |

DF08-01/0.N.05 |

1 |

Hai Hong |

|

14 |

Bidirectional hydraulic lock |

HR-012 |

1 |

ATOS |

|

15 |

liquid level switch |

KYT-020 |

1 |

Hydfly |

|

16 |

Air cooler |

HFFL-88 |

1 |

Hydfly |

|

17 |

Pass-through check valve |

S15A5.0/2 |

1 |

Huayuan |

|

18 |

one-way throttle valve |

HQ-012 |

1 |

ATOS |

|

19 |

circuit breaker |

GV2-ME20C |

1 |

Schneider |

|

20 |

contactor |

LC1-D25M7C |

1 |

Schneider |

|

21 |

Switching Mode Power Supply |

LRS-200-24 |

1 |

Mingwei |

|

22 |

PLC |

I3V-9B02H-YQ (standard modular PLC) |

1 |

Hydfly |

|

23 |

touch screen |

HFP6070T |

1 |

Hydfly |

|

24 |

fuse |

RT28-32-1P (base)/RT28-32-10A (core) |

1 |

Chint |

|

25 |

audible and visual alarm |

AD16-22SM/R23 |

1 |

Two jobs |

|

26 |

mains switch |

LW39-25-N4/3 |

1 |

Two jobs |

|

27 |

push-button |

XB2BA51C |

1 |

Schneider |

|

28 |

push-button |

XB2BA3311C |

1 |

Schneider |

|

29 |

push-button |

XB2BA3341C |

2 |

Schneider |

|

30 |

emergency stop switch |

XB2BS542C |

1 |

Schneider |

|

31 |

key switch |

XB2BG03C |

1 |

Schneider |

|

32 |

junctor |

TyP2823 |

1 |

Wipu |

|

33 |

junctor |

TyP585 |

1 |

Wipu |

|

34 |

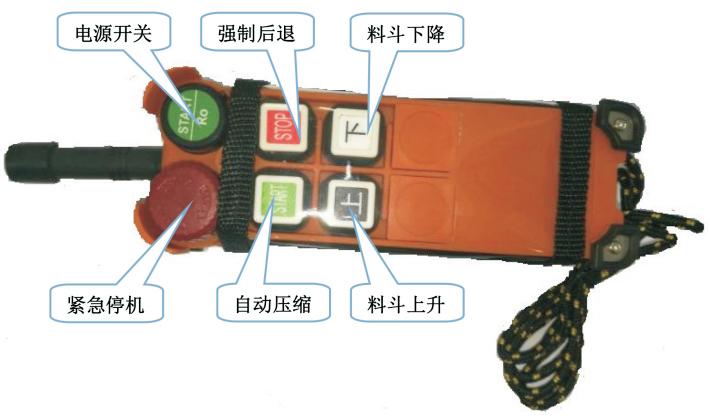

Wireless remote control |

WCT-K4 |

1 |

Viktor |

|

35 |

The steering handle |

YQA1-5K |

1 |

Fangshan |

dumping gear:

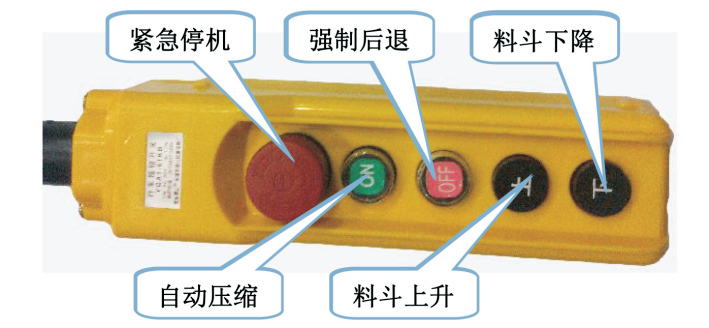

The tipping bin is powered by an onboard hydraulic system, with a rated lifting capacity exceeding 1000 kilograms. The process of lifting and tipping the garbage bin is smooth, stable, and produces minimal noise. The large tipping bin, integrated with the compression head, has a volume greater than 3m³, suitable for feeding into trash bins, wheelbarrows, and mini collection vehicles. It is equipped with a remote control panel, effectively preventing dust and wastewater from being generated during operation.

The operation process of the inverted bucket type mobile integrated compression equipment is as follows: garbage collection-> garbage feeding-> garbage compression-> box loading and unloading-> garbage transfer-> garbage unloading from the box-> entering the next round of garbage collection.

Compression chamber:

The sewage tank is set at the bottom of the front end of the compression chamber, which is more conducive to the storage, discharge and cleaning of sewage, effectively protect and extend the service life of the main hydraulic cylinder, reduce the difficulty and times of garbage cleaning in the rear end of the garbage compression chamber, and significantly reduce the workload of sanitation workers.

The sewage discharge channel of the head adopts the design of straight pipe at both ends, which is conducive to sewage discharge and cleaning blockage. The pipe opening adopts fire protection special safety drainage valve, with large diameter and good sealing performance, so as to prevent the leakage of sewage in the transportation process.

The compression chamber is equipped with a fixed claw hook to prevent the garbage from bouncing back.

Container: the outer arc design is beautiful and generous; the inner four corners are rounded, the front of the box (referring to the part combined with the compressor head) is small and the rear (referring to the part combined with the rear door) is large, so that the garbage can be completely dumped without leaving any residue.

Hydraulic system: using imported well-known brand valve group, oil pump and special cylinder, through optimized design, oil temperature control and equipment reliability is higher than domestic similar products.

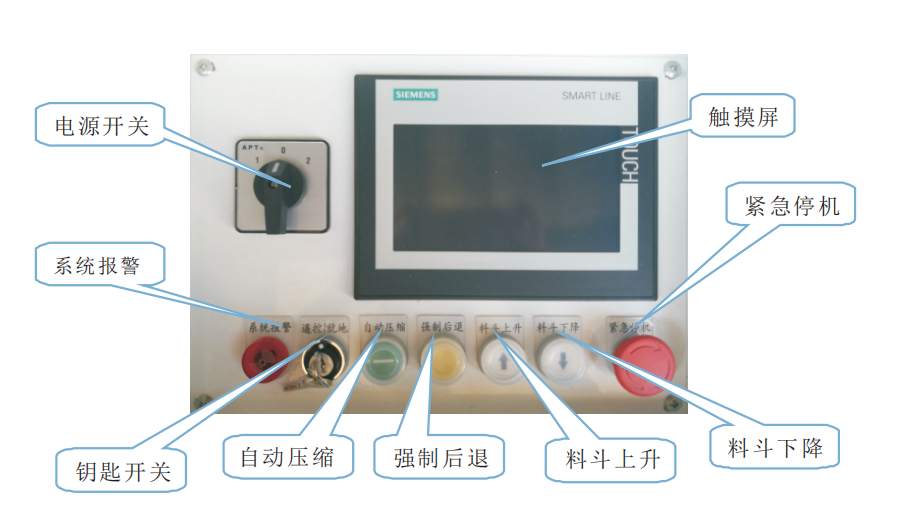

intelligent control system:

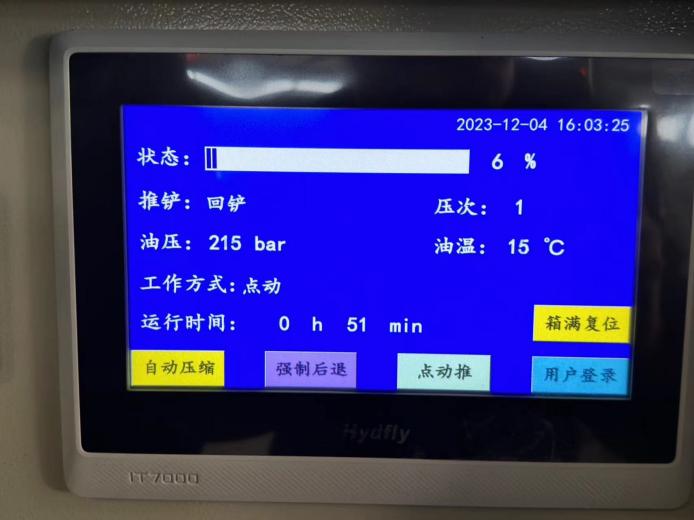

A) Intelligent control and accurate display of equipment operation status:

A. Control system: can realize the separate movement of each action, interlocking between each action, electro-hydraulic control, intelligent program control; safe and simple operation, high reliability.

B. Intelligent system: can remember the operation record, automatically check and reflect the possible problems of the compressor and prompt;

C. Display system: can display the operating conditions of the compression device, operation records and loading conditions of the box;

D. Safety protection system: automatic shutdown when the box is full, prompt transfer and avoid overload. The operation panel is equipped with protective devices for safety and reliability.

B) Reasonable application of science and practice, reduce energy consumption and effectively save the use cost: ABB or Siemens special motors with power of 5.5Kw are adopted to ensure the actual application while reducing energy consumption and saving operation cost for users.

Sealing of discharge door (rear door):

The back door is embedded with an integral EPDM rubber sealing strip, which has strong stretchability, high durability and better sealing performance, which can effectively prevent the leakage of sewage and is easy to maintain and replace.

Through practical use, when the moisture content of garbage is 30%, which is equivalent to the highest moisture content of garbage in southern cities in summer, 100% sealing performance is guaranteed during the compression and transportation process.

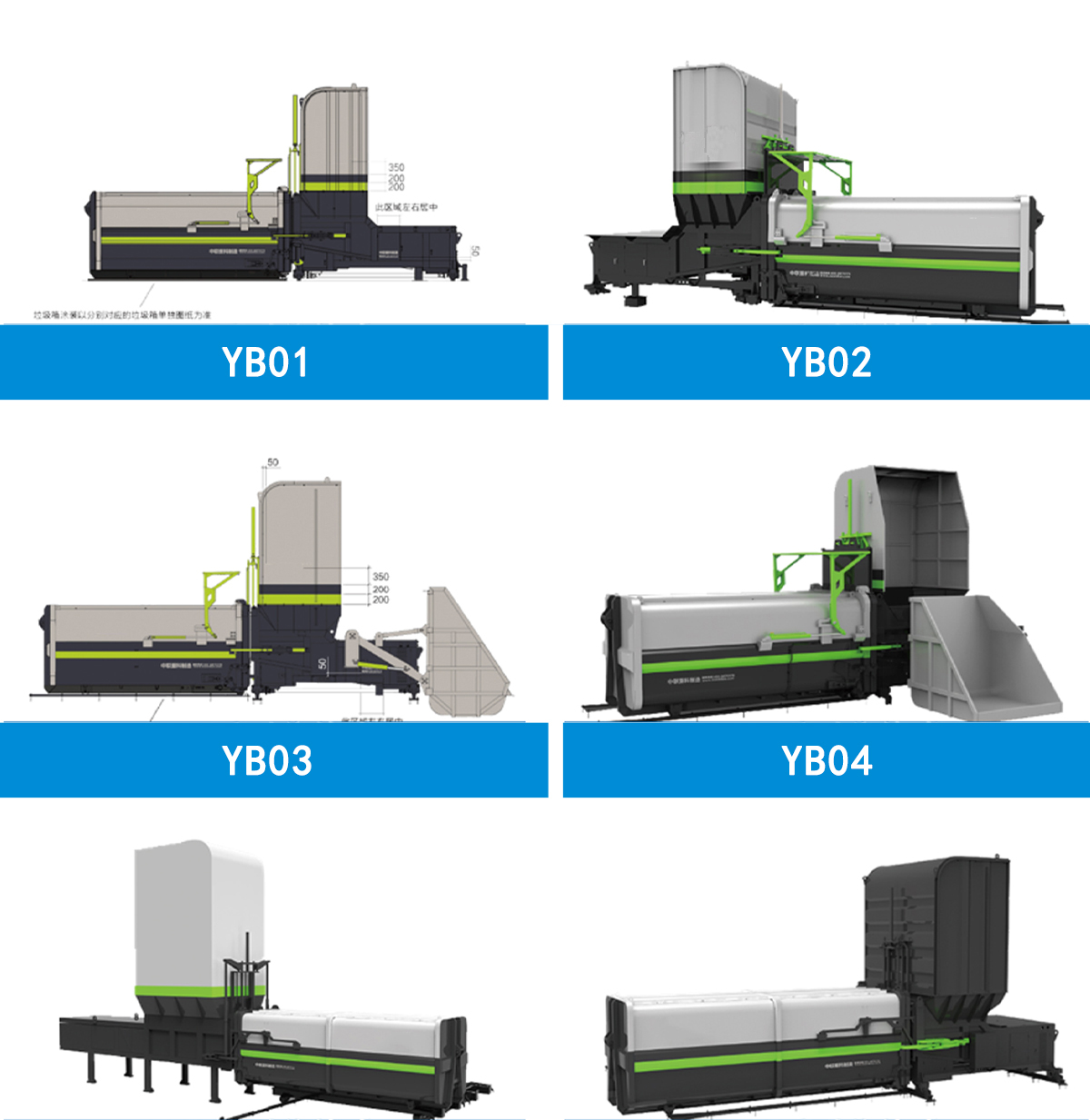

Introduce the model of intelligent mobile integrated garbage compactor

Main technical parameters of 8 cubic inverted bucket compression box

|

Technical projects |

technical parameter |

|

model |

FB08 |

|

compressive force (T) |

≥25 |

|

Running noise dB |

≤75 |

|

Compression chamber stroke volume (m3) |

1 |

|

Head-up cycle time (S) |

40 |

|

Effective area of compressed pusher (mm) |

1600×500 |

|

Central height of hook / outer width of guide rail (mm) |

1570/1060 |

|

power of motor (Kw) |

4/5.5 |

|

source |

380V. Three-phase. 15A, waterproof design |

|

Vessel volume (m3) |

8 |

|

Reversal hopper volume (m3) |

≥2 |

|

Size: length * width * height (mm) Length is the distance from the hook to the tailgate |

4300×2500×2450

|

|

Total weight (kg) |

4500 |

Main technical parameters of 12 cubic meter flipping bucket compression box

|

Technical projects |

technical parameter |

|

model |

FB12 |

|

compressive force (T) |

≥34 |

|

Running noise dB |

≤75 |

|

Compression chamber stroke volume (m3) |

1.2 |

|

Head-up cycle time (S) |

43 |

|

Effective area of compressed pusher (mm) |

1900×500 |

|

Central height of hook / outer width of guide rail (mm) |

1570/1060 |

|

power of motor (Kw) |

5.5/7.5 |

|

source |

380V. Three-phase. 15A, waterproof design |

|

Vessel volume (m3) |

12 |

|

Reversal hopper volume (m3) |

3.1 |

|

Size: length * width * height (mm) Length is the distance from the hook to the tailgate |

5260×2500×2450

|

|

Total weight (kg) |

5100 |

Main technical parameters of 18/20/25 cubic inverted bucket compression box

|

Technical projects |

technical parameter |

technical parameter |

technical parameter |

|

model |

FB18 |

FB20 |

FB25 |

|

compressive force (T) |

≥34 |

≥34 |

≥34 |

|

Running noise dB |

≤75 |

≤75 |

≤75 |

|

Compression chamber stroke volume (m3) |

1.2 |

1.2 |

1.2 |

|

Head-up cycle time (S) |

45 |

45 |

45 |

|

Effective area of compressed pusher (mm) |

1900×500 |

1900×500 |

1900×500 |

|

Central height of hook / outer width of guide rail (mm) |

1570/1060 |

1570/1060 |

1570/1060 |

|

power of motor (Kw) |

7.5 |

7.5 |

7.5 |

|

source |

380V. Three-phase. 15A, waterproof design |

380V. Three-phase. 15A, waterproof design |

380V. Three-phase. 15A, waterproof design |

|

Total volume of the tank (m3) |

18+3.5 |

20+3.5 |

25+3.5 |

|

Reversal hopper volume (m3) |

3.1 |

3.1 |

3.1 |

|

outline dimension: Length * Width * Height (mm) Length refers to the distance from the hook to the tailgate |

6500×2500×2570

|

6700×2500×2570

|

7260×2500×2600

|

|

hydraulic jack |

Hengli |

Hengli |

Hengli |

|

Maximum compressive force (kn) |

More than 40 tons |

More than 40 tons |

More than 40 tons |

|

Total weight (kg) |

6400 |

6600 |

7000 |

Separate bins

In addition, 22 and 28 separate garbage bins can be customized for production and used with supporting garbage compression transfer stations.

The 22 square meter box is matched with a double bridge hook arm vehicle. The box size is 5990*2530*2580, the effective volume is 22 square meters, and the self-weight is 5380KG.

The 28 square meter box is matched with a four-front eight-back hook arm vehicle. The box size is 6800*2530*2580, the effective volume is 28 square meters, and the self-weight is 5960KG.

It can be customized according to the size of the compressor station.

Product Details Display

Reviews

There are no reviews yet.